Standard Equipment | Optional Equipment |

▼ Raycus or Max laser source | ▽ IPG or nLIGHT laser source |

| ▼ WSX or RayTools laser cutting head | ▽ PRECITEC laser cutting head |

| ▼ GENUO-Cypcut control software | ▽ Beckhoff CNC control system |

| ▼ High strength stress relieved frame | ▽ Automatic tube feeding system |

| ▼ Φ220 Auto pneumatic chuck | ▽ Φ350 Auto pneumatic chuck |

| ▼ Motovario planetary reducer | ▽ Alpha planetary reducer |

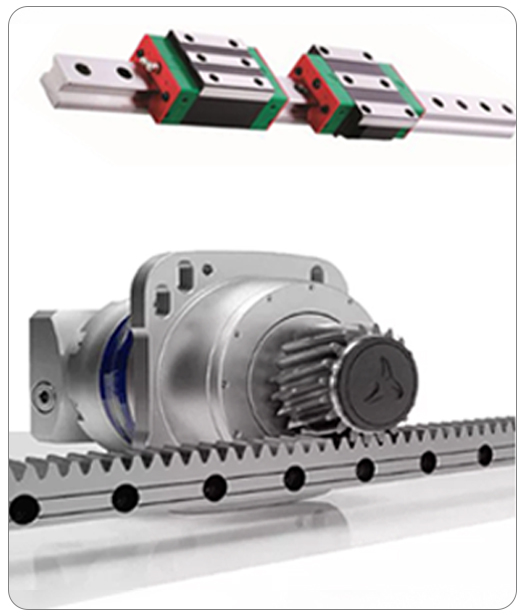

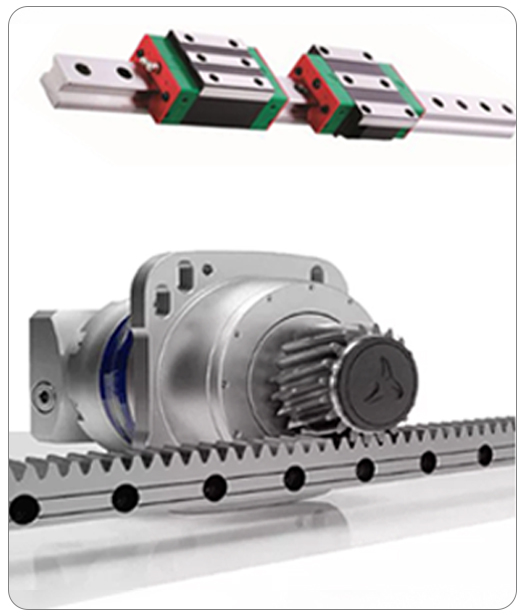

| ▼ YYC gear rack,HIWIN guide rail | ▽ Atlanta gear rack,Rexroth rail |

| ▼ Hanli water cooling system | ▽ Power regulator Device |

| ▼ Automatic lubrication system | ▽ Air compression system |

Configuration Details

The special pipe laser cutting machine consists of 7 aixs

It can realize the cutting of round, square, rectangular and

elliptical pipes

It can realize the one-time forming and processing of 6-meter pipe,

and

can be equipped with 9-meter and 12-meter pipe cutting machines

with

different pipe lengths and diameters.

The equipment is matched with feeding shaft and pulling shaft,

which can

greatly reduce the waste of processing tailings

It can cut multiple pipes with different directions and diameters

on the main pipe

It can cut variable angle groove surface

It is known as pipe cutting machine and material expert in the

industry.

|

|

|

| Front Pneumatic Chuck | Rear Pneumatic Chuck | Special Support |

Intelligently detect the jaw status and easily obtain pipe data. | Automatically match the app- ropriate air pressure and adjust the clamping force. | Avoid sagging and deformation of pipes, improve cutting accuracy. |

Main Accessories

|

|

| Advanced Laser Generator | Intelligent Cutting CNC Control |

Standard configuration of stable and efficient Raycus or MAX laser generator. Modular design, highly integrated system, free from maintenance, high reliability.

The laser power is continuously adjustable, with high beam quality and high laser stability. It is an ideal laser source for laser fine cut, precision welding and other applications. Compared with other similar lasers in the market, our laser has obvious advantages. Optional IPG and nLIGHT Laser. | The whole series of laser cutting machines are equipped with CypCut laser cutting control software or HypCut ultra-high power laser cutting control software.With high accuracy visual positioning system and integrated CNC system successively. It is easy to use and has powerful functions, which can meet and apply to various process -ing occasions. In addition, it has WiFi remote control function. Escort your machine wherever it is used. Optional Germany PA8000, Siemens CNC cutting system |

|

|

| Powerful Clamping System | High Strength Heavy Frame |

Standard configuration of stable and efficient Raycus or MAX laser generator. Modular design, highly integrated system, free from maintenance, high reliability.

The laser power is continuously adjustable, with high beam quality and high laser stability. It is an ideal laser source for laser fine cut, precision welding and other applications. Compared with other similar lasers in the market, our laser has obvious advantages. Optional IPG and nLIGHT Laser. | Standard configuration of stable and efficient Raycus or MAX laser generator. Modular design, highly integrated system, free from maintenance, high reliability.

The laser power is continuously adjustable, with high beam quality and high laser stability. It is an ideal laser source for laser fine cut, precision welding and other applications. Compared with other similar lasers in the market, our laser has obvious advantages. Optional IPG and nLIGHT Laser. |

|

Exactly Matched Laser Head

All Genuo laser cutting machines are standard equipped with WXS or Raytools auto-focusing laser cutting heads.

The cutiing heads have a built-in motor drive unit, which drives the focusing lens through a linear mechanism to change position automatically.

Customers can set the program to achieve continuous focus that completing the rapid piercing and cutting material with different thickness.

The design of water-cooled structure allows laser heads to work stably and chronically.

Optional PRECITEC and Lasermech laser cutting heads.

|

|

High Precision Transmission Parts

Special Japanese SHIMPO or French Motovario flange reducer, precision rack and pinion, silent linear guide.

Connect the lathe bed and the cutting part precisely.

Let the machine run in a very smooth and efficient way.

With the automatic lubrication system, the maintenance of mechanical parts is greatly reduced.

Optional Atlanta reducer, rack and pinion.

|

|

Superior Quality Electrical Components

The machine adopts Japanese Fuji or Panasonic servo motor and drive up to 6000r / min.

Powerful torque and power greatly improve the cutting efficiency.

At the same time, it has extremely accurate positioning accuracy and long service life.

The main electrical accessories are Schneider and Siemens, reasonable line connection and optimization.

Ensure a very low failure rate.

Optional Yaskawa servo motor and drive.

|

Optional Installation

|

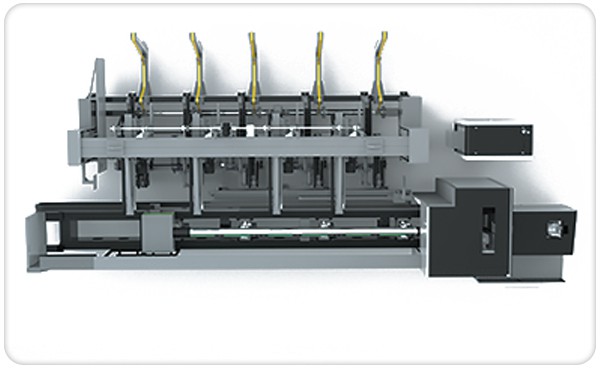

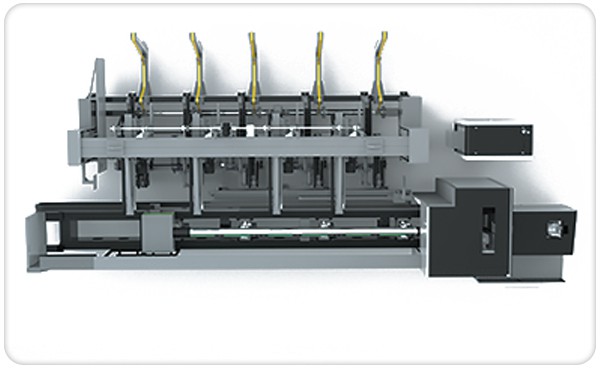

Automatic Feeding System

Saving labor cost .

With semi-automatic or full-automatic loading and unloading system, reduce the dependence on labor, reduce the labor intensity of the operator, make the pipe cutting so easy.

|

| Air Compression System

Special for laser cutting, it adopts integrated air compressor, air receiver, cold dryer, filter element, direct connection low resistance design.

Sufficient flow, giving play to better cutting performance.

The side exhaust air is designed to dissipate heat and is not easy to accumulate dust.

Automatic and manual dual blowdown design to remove residual substances.

Four stage filtration, YUKA brand, filter. Front mounted black oil mist filter, with good water and oil removal effect.

The filtration precision of over setting oil and water removal can reach 0. 01PPM.

|

|

Power Stabilizer

Unstable voltage can cause mortal injury or equipment malfunction, affect production, cause delivery delays,and unstable quality.

At the same time, it accelerates the aging of the equipment, affects the service life and even burns the parts, so that the owner is faced with the problem of repairing or having to update the equipment in a short period of time, wasting resources;

In severe cases, even security incidents can occur, causing incommensurable osses. Therefore, Therefore.

If your factory voltage fluctuates greatly or is unstable, it is necessary to use a voltage Stabilizer.

|

Features

The cutting machine adopts international famous brand advanced

laser, which has high electro-optical efficiency, water-saving

and power-saving. Especially important, it can be free of

maintenance for a long time, save a lot of maintenance funds and

time,

and improve work efficiency.

The overall main frame adopts gantry structure worktable.

The high damping bed has good rigidity, high precision and stable

operation.

The frame structure is made of high-quality steel honeycomb

welding. The machine tool is annealed, twice aged and processed

by large-scale gantry milling machine. These design and processing

means ensure that the machine tool has excellent seismic

resistance, high rigidity and stability. It fully meets the

stability requirements of the machine tool in high-speed motion.

The high precision double side rack and pinion drive and linear

guide rail are adopted, and the powerful dual drive servo motor

drive system is used to effectively ensure the speed and accuracy

of laser cutting.

Also can choose the exchange type worktable, the failure rate is

extremely low, the exchange time is short,

greatly improves the production efficiency.

Cutting Ability

GENUO laser cutting machine has powerful cutting ability, "flying"

cutting speed, ultra-high stability,

high quality processing, extremely low operating cost and

ultra-high adaptability.

Technical Parameter

Hot Tags: CYCLONE GNAT Tube Series Laser Cutter, China, suppliers,

manufacturers, factory, price, cost, cheap, for sale,